Working pewter

We receive tin in ingots. Here, we have 1 ton.

We receive tin in ingots. Here, we have 1 ton.

Ingots are melted in a melting-pot to achieve our 95% pure pewter alloy.

Ingots are melted in a melting-pot to achieve our 95% pure pewter alloy.

Our foundry.

Our foundry.

Two casting processes :

Depending on the products, several casts can be necessary to craft the final product.

I) Gravity casting :

The operative pours the exact measure of pewter in the steel cast using a ladle.

The operative pours the exact measure of pewter in the steel cast using a ladle.

After a solidification delay, the cast opens automatically, releasing the pewter piece.

After a solidification delay, the cast opens automatically, releasing the pewter piece. The operative removes the still hot piece, then closes the cast and starts over.

The operative removes the still hot piece, then closes the cast and starts over.

II) Centrifugation casting :

The cast is placed in the centrifuge (which closes) and starts rotating.

The cast is placed in the centrifuge (which closes) and starts rotating.

The operative pours the exact measure of pewter in the silicone cast using a ladle.

The operative pours the exact measure of pewter in the silicone cast using a ladle.

After a solidification delay, the centrifuge opens, releasing the cast.

After a solidification delay, the centrifuge opens, releasing the cast. The operative removes the still hot piece, then closes the cast and starts over.

The operative removes the still hot piece, then closes the cast and starts over.

The pewter inlets are cut by sawing.

The pewter inlets are cut by sawing. The base and the neck of the pitchers, soup tureens,... are mounted together to be welded.

The base and the neck of the pitchers, soup tureens,... are mounted together to be welded. The welding of the two pieces is done without any metal filling.

The welding of the two pieces is done without any metal filling.

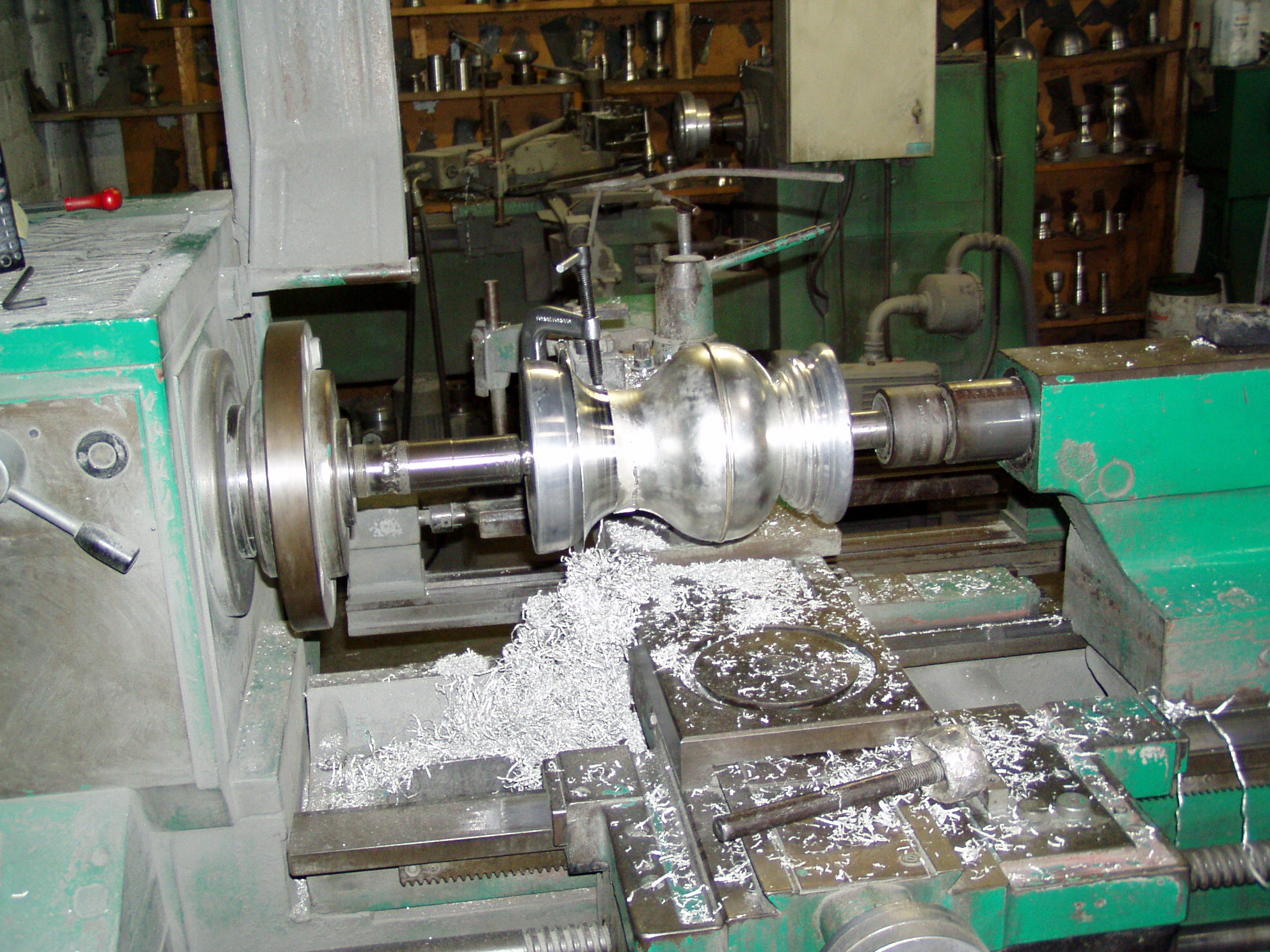

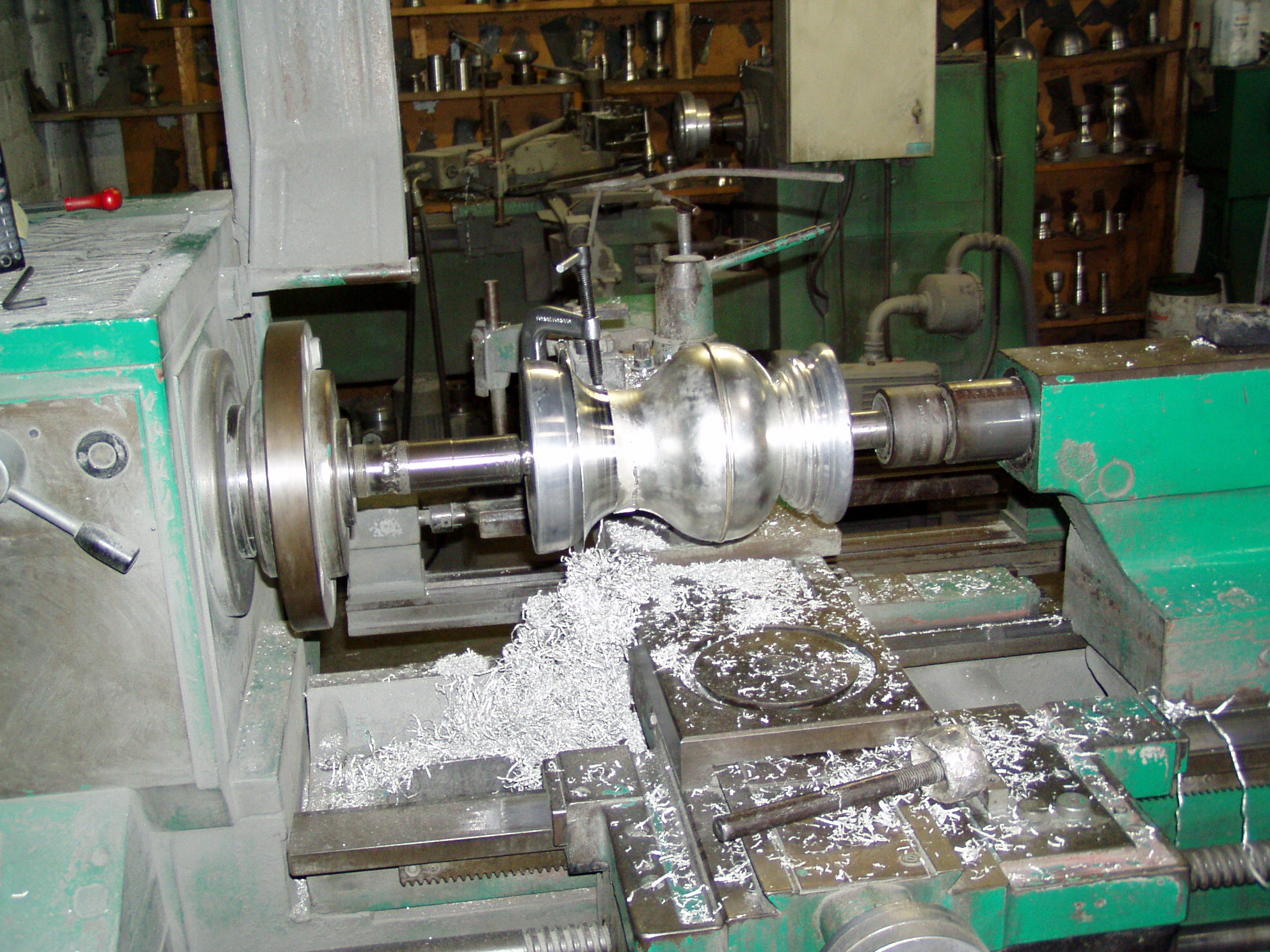

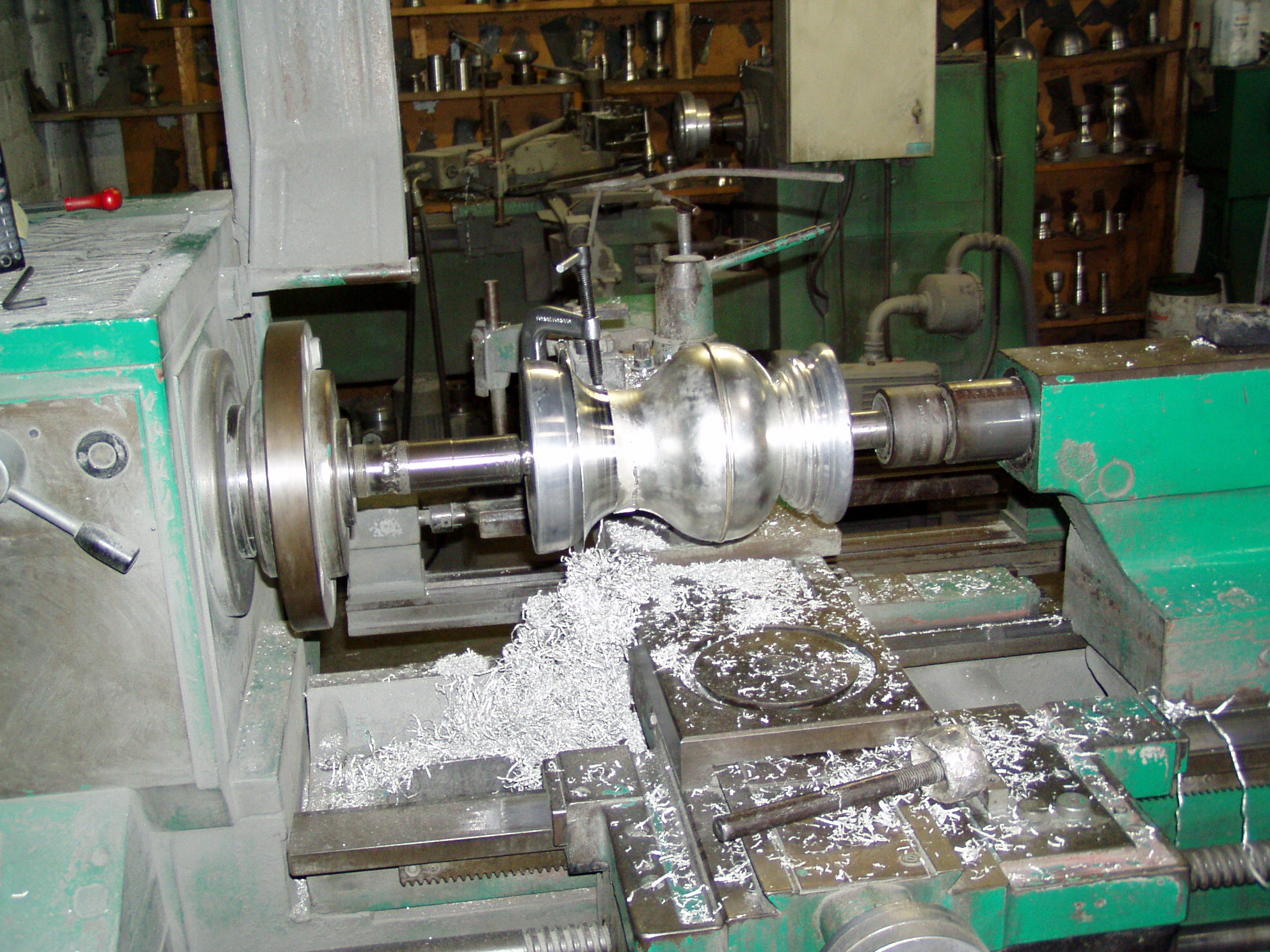

Some of our lathes.

Some of our lathes.

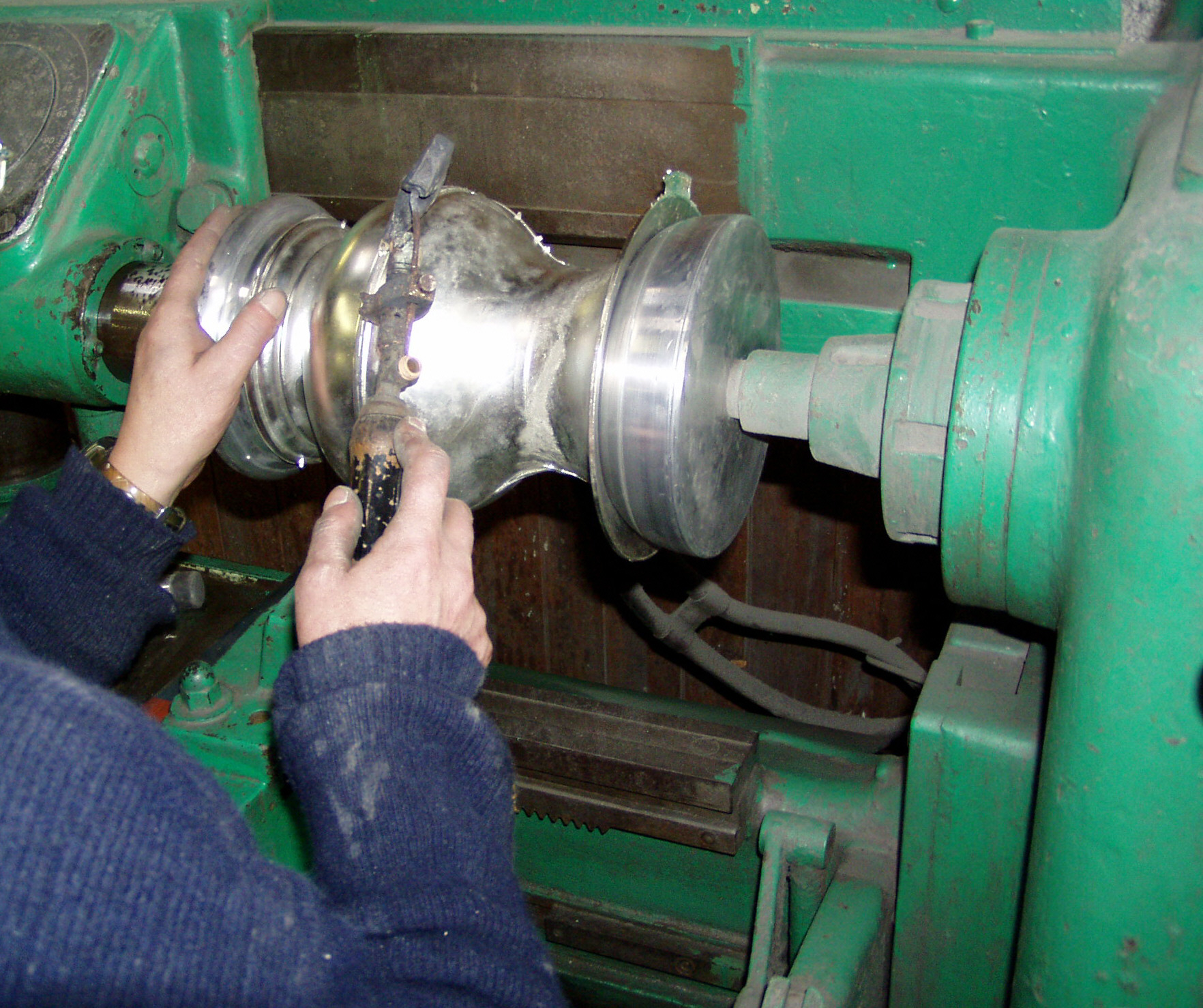

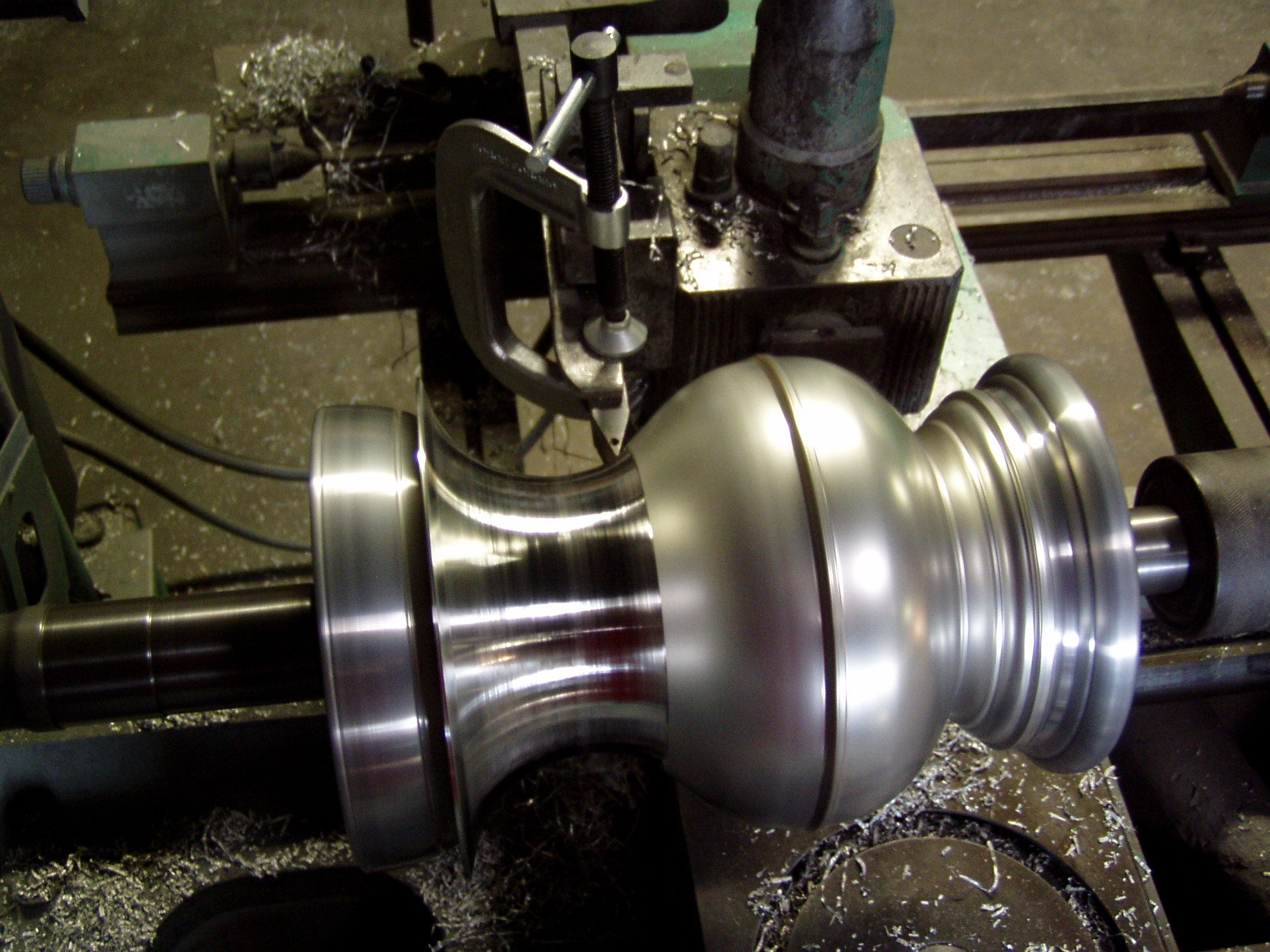

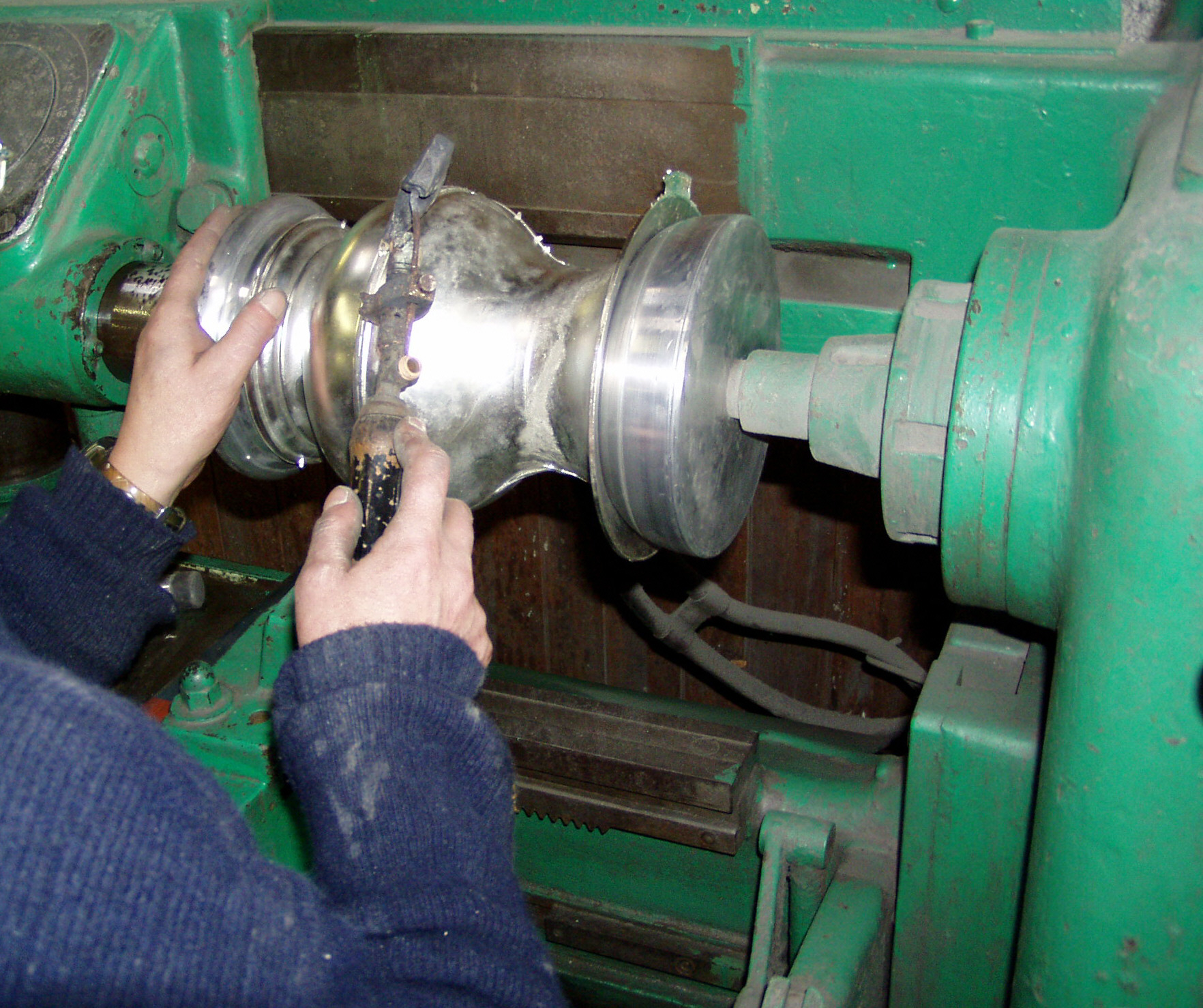

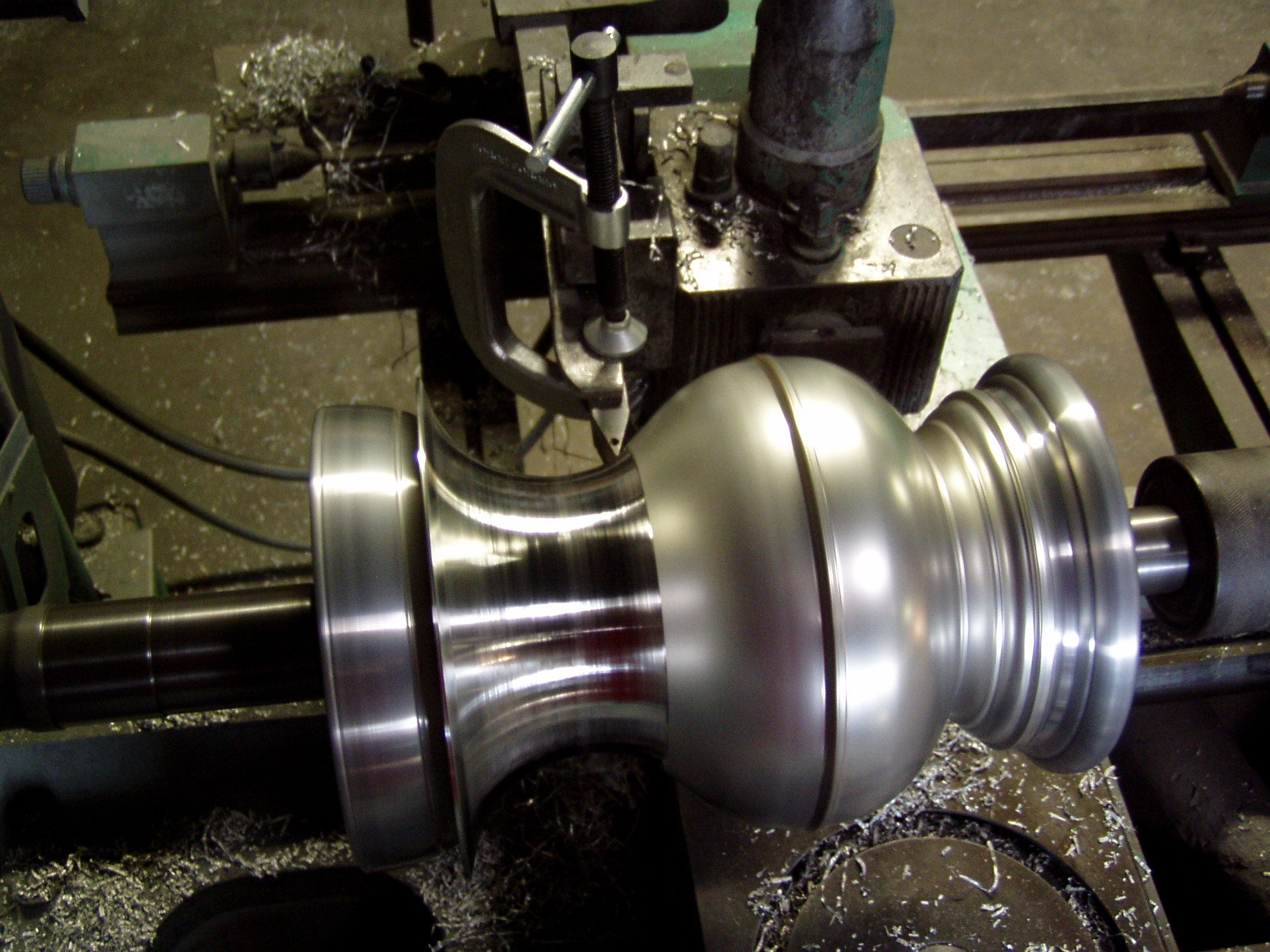

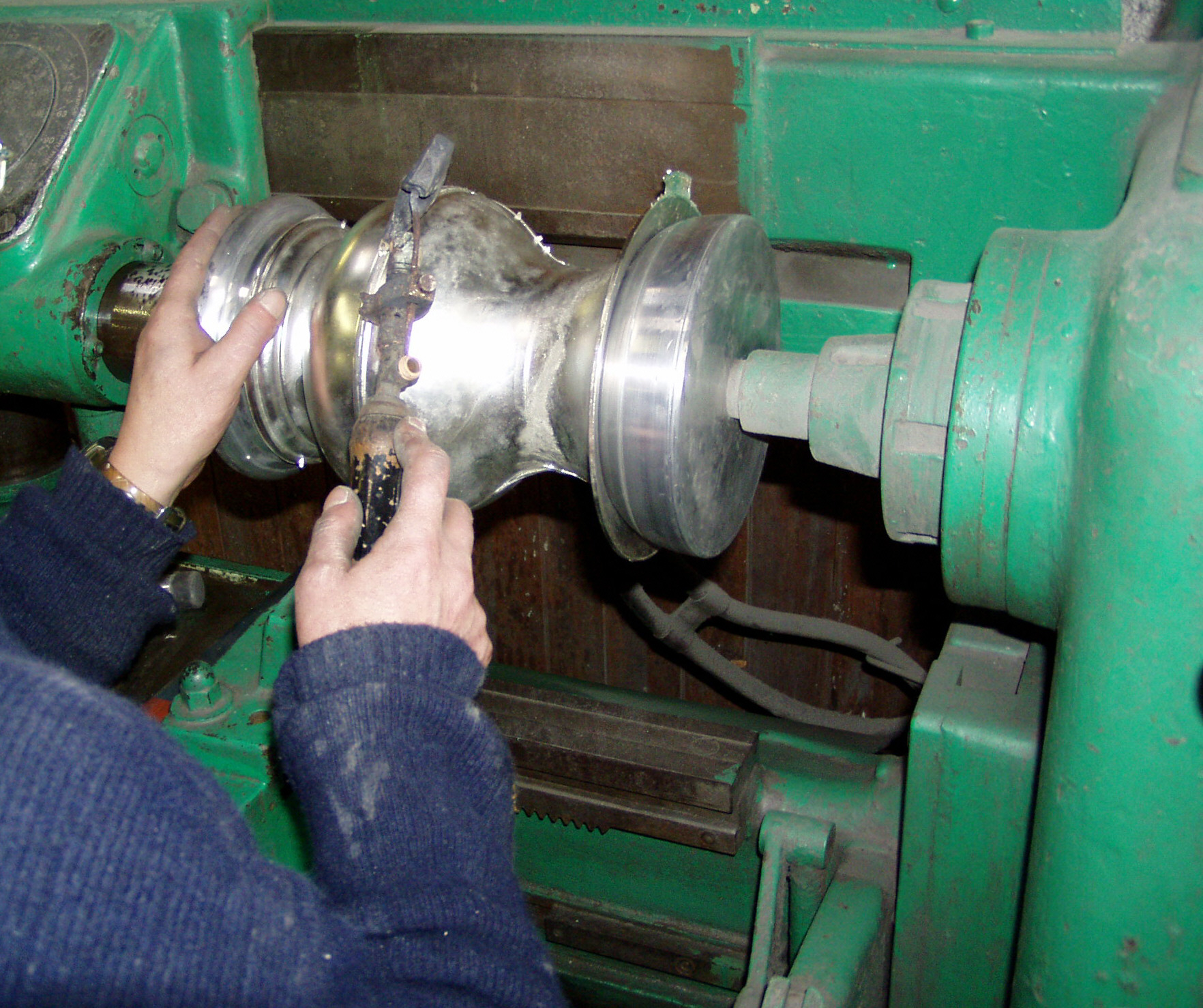

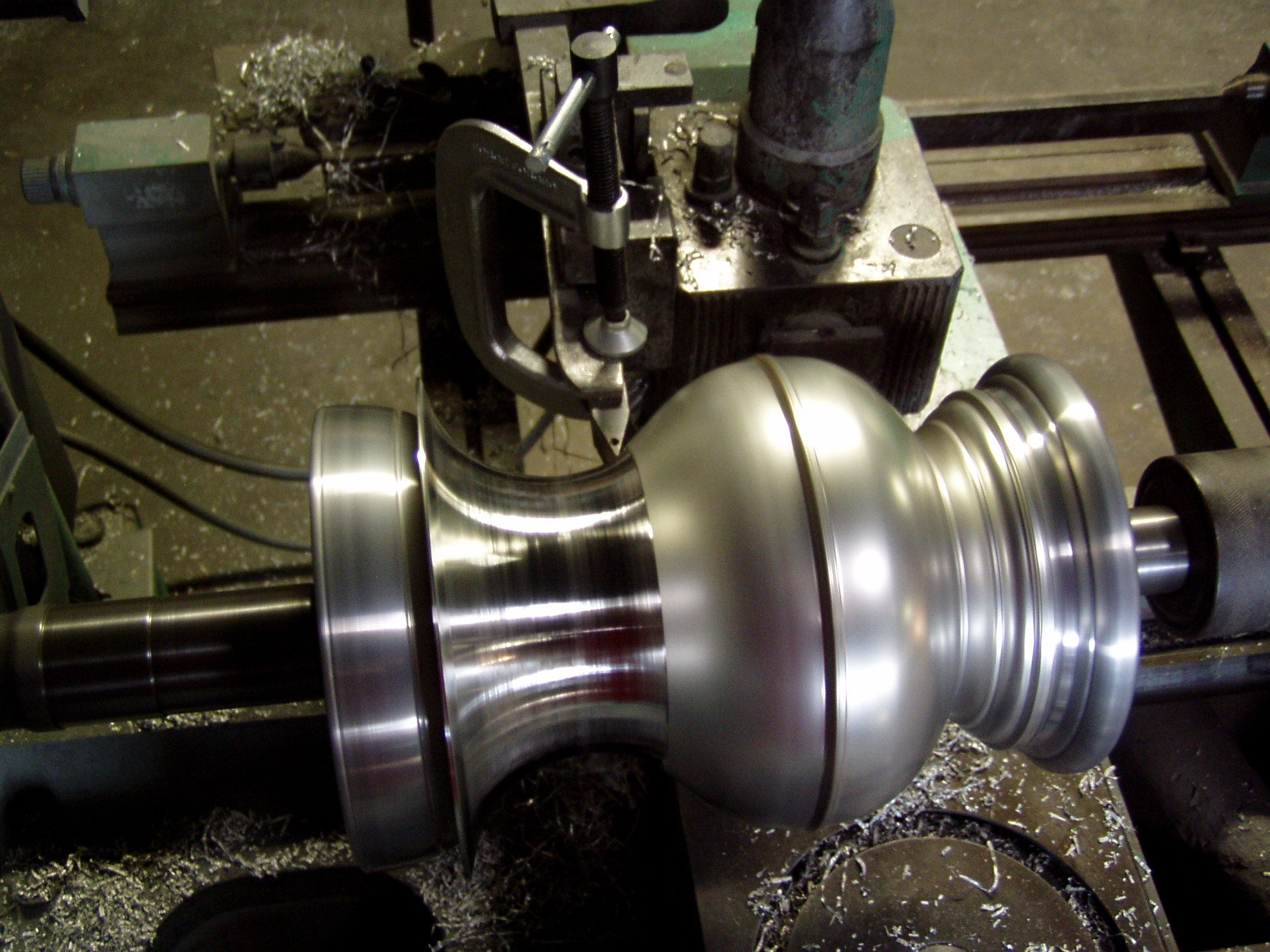

The products are then lathed using a copying process.

The products are then lathed using a copying process.

When lathed, the products are pre-polished by hand using a "blade"

When lathed, the products are pre-polished by hand using a "blade"

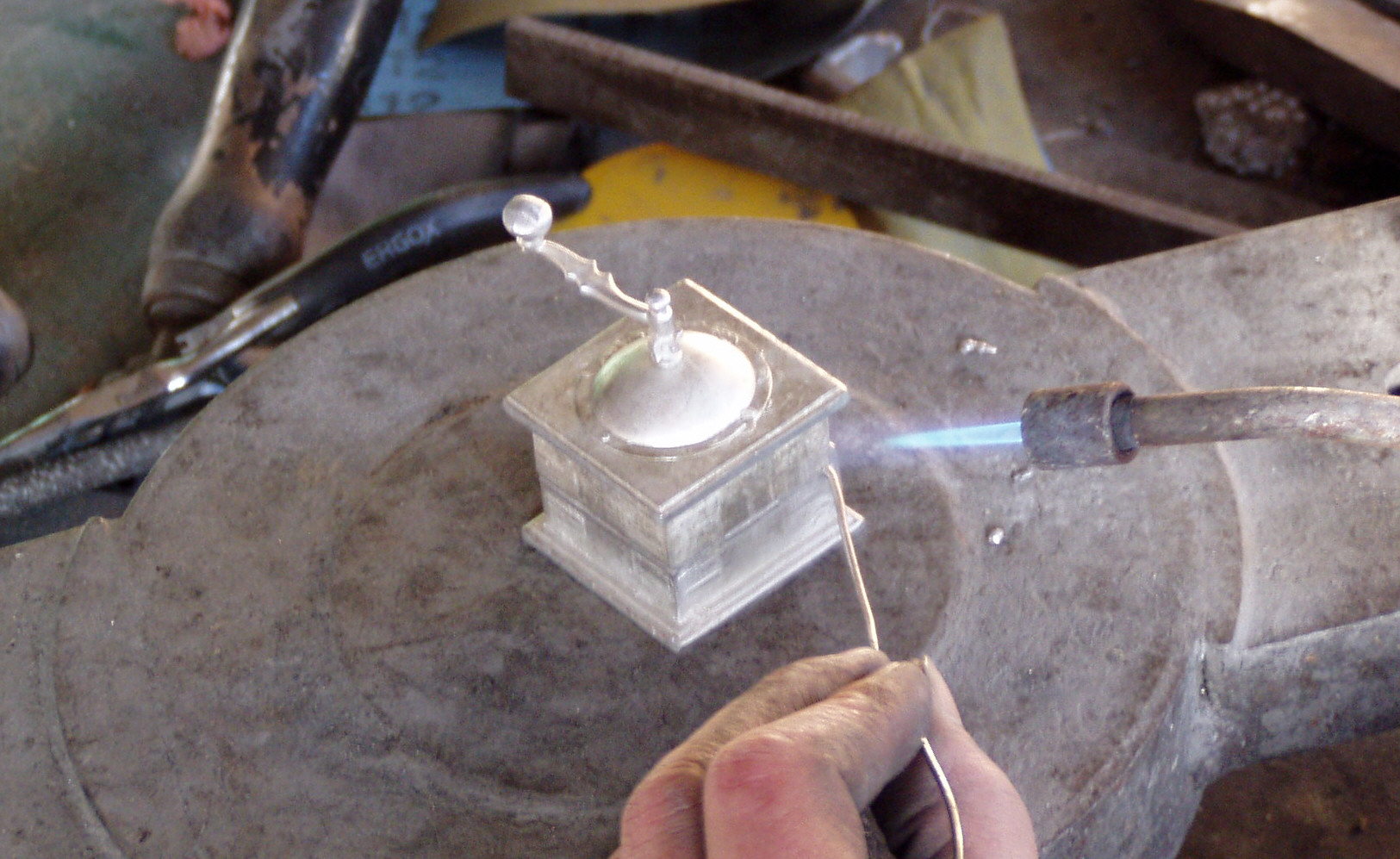

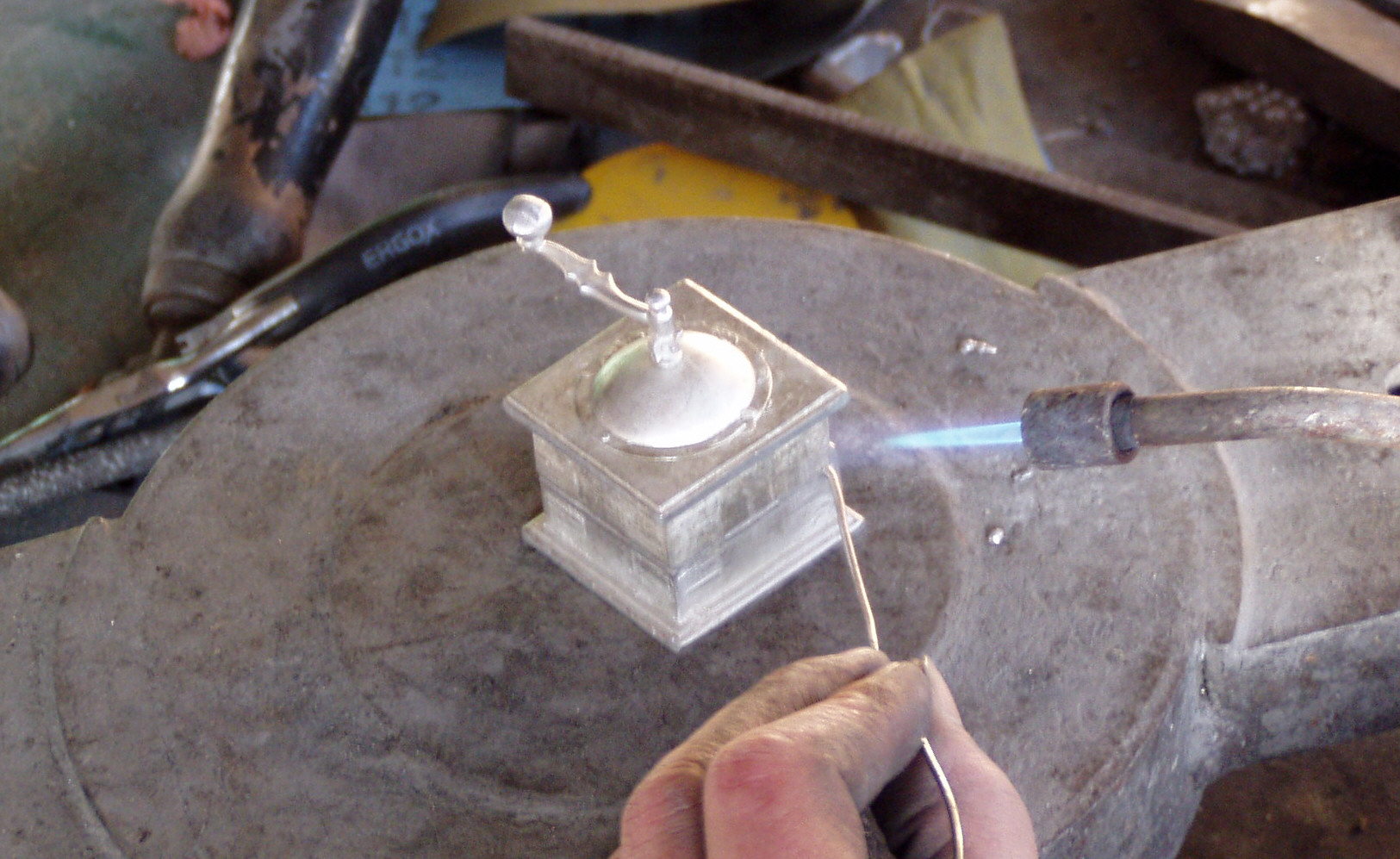

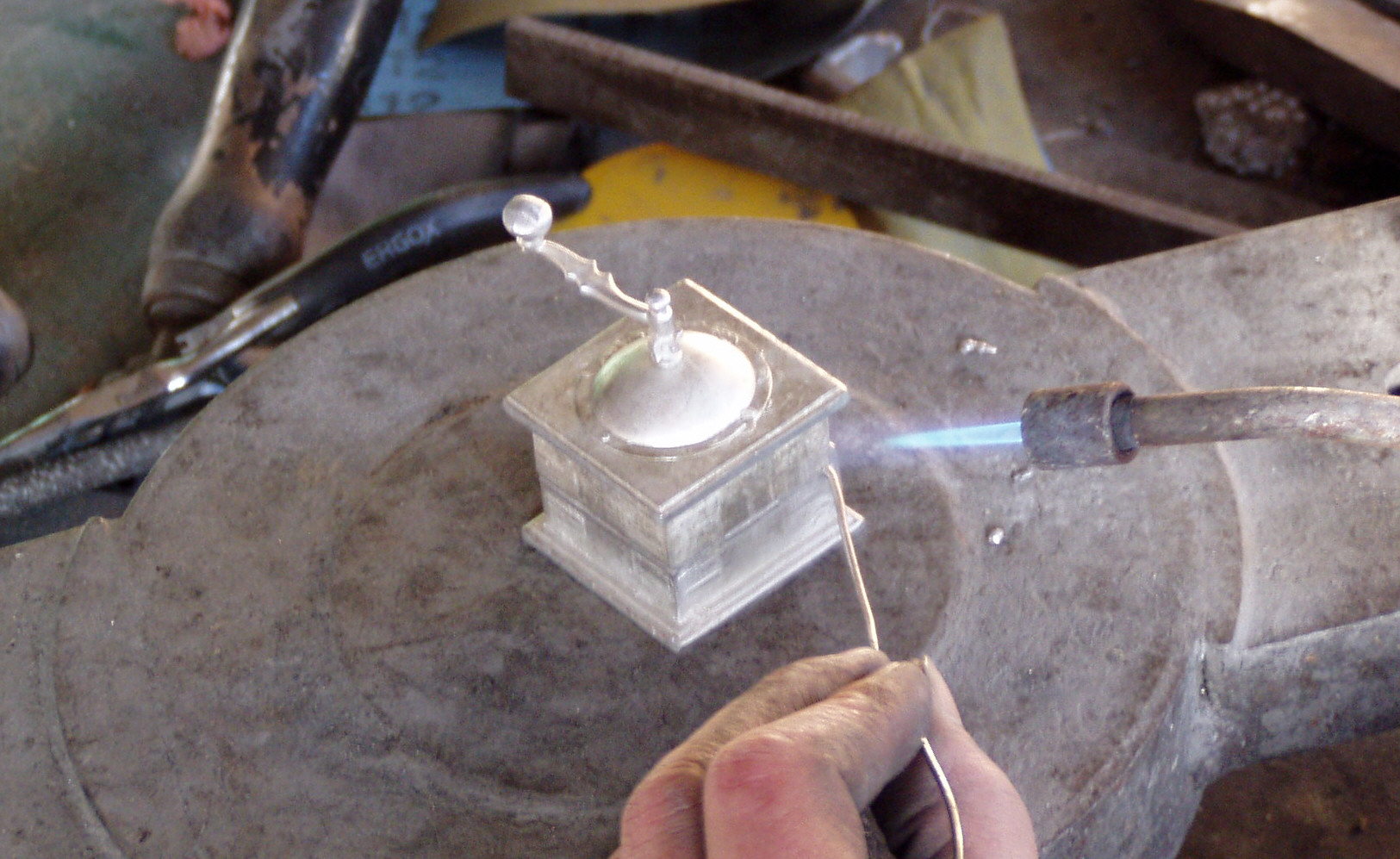

After inspecting the pieces, the handles, grapes and other decors are welded.

After inspecting the pieces, the handles, grapes and other decors are welded.

Welding of a miniature object.

Welding of a miniature object.

This requires great experience.

Once the product is completely mounted, all the products go in a steel ball machine to be polished and aged.

Once the product is completely mounted, all the products go in a steel ball machine to be polished and aged. After aging and oxidation, the final patina is obtained by brightening on flannel discs using polishing wax.

After aging and oxidation, the final patina is obtained by brightening on flannel discs using polishing wax.